Vraag

How do you optimize logistics processes so that they become more proactive and tactical?

Matthias Lootens, Maintenance Engineer at Port of Antwerp: "The project with Gordian resulted in increased insight into warehouse operations and confirmation of the company’s interests."

Aanpak

Professionalisation in phases

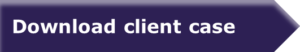

Port of Antwerp manages and maintains the docks, bridges, locks, quay walls, service buildings and land in the port of Antwerp. These assets are crucial for the functioning of the port. In order to carry out these management and maintenance activities as effectively and efficiently as possible, Port of Antwerp invested in the optimisation of its supply chain processes. Gordian and Port of Antwerp organised several workshops with employees from all departments, to review the current processes and work towards a 'To Be' situation. Gordian then drafted procedures for requesting materials, creating new article numbers, drawing up Critical Parts lists, purchasing and warehouse processes among other things. In addition to a clear process flow, Gordian also drafted concrete work agreements. This includes requesting purchase confirmations, making a reservation on a work order or issuing material on presentation of an approved work order. In addition, Gordian connected the Spare Parts Management (SPM) Studio to the Maintenance Management system Maximo. With the help of the SPM Studio and the wishes of the maintenance engineers and warehouse managers, optimal reorder points and order sizes are periodically determined. And with the introduction of a KPI dashboard and a ‘Plan Do Check Act’ cycle, Port of Antwerp gains more insight into the performance of the supply chain. In this way, one can aim for continuous improvement.

Resultaat

Better collaboration and improved information sharing

The new work processes led to better collaboration and more information sharing between the warehouse and internal customers. This also increased understanding between the different departments. By applying the new inventory parameters, Port of Antwerp is able to manage its stock in a better way. This results in reliable stock, without having too much in stock. The introduction of the Plan Do Check Act cycle ensures that this reliable stock is maintained with a high service level for the service technicians and a healthy cost level for the controller. This is an ongoing process that requires continuous attention. The process has resulted in increased insight into warehouse operations and confirmation of the company’s interest.