Question

How can an optimization tool help you optimize consumables and rotables?

Robin Verkerk, Team supervisor Supply Chain Rail materials: “The Spare Parts Management Studio helps GVB to improve performance and to be in control of a wide range of spares.”

Approach

Implementation of the Spare Parts Management Studio

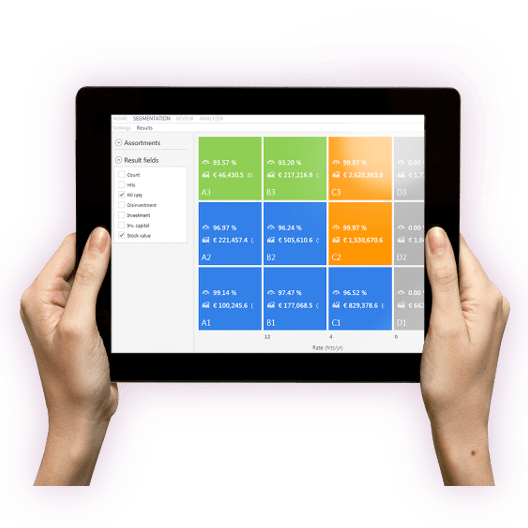

GVB is the public transport company of Amsterdam. Gordian and GVB worked together to professionalize the inventory control of spare parts. GVB requested support from Gordian by optimizing the inventory by making use of an optimization tool. The Spare Parts Management (SPM) Studio is an optimization tool with analysis, reporting and export features. Gordian implemented processes within this tool.

Output from the SPM studio are optimal stock control parameters with which GVB enriches its ERP system. Gordian built a KPI dashboard to enable GVB to measure their performances. The dashboard is equipped with useful exports at part level to quickly identify the sore spots.

Result

Ensure continuous improvement driven by a tactical planner

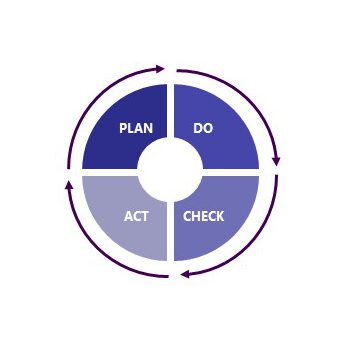

An improvement cycle is needed to guarantee improvement of results. Gordian trained GVB to implement a continuous improvement cycle for consumables. These acquired skills are used by the tactical planner to calculate inventory control parameters, analyse the performance and initiate improvement actions when necessary.

In order to improve further, Gordian supports GVB to professionalize by means of a KPI report, optimization of rotables and by a provisioning model.