Question

How does collaboration improve processes and (spare) parts availability?

Erik van de Poel – Manager Operations & Supply Chain “Solid expertise in understanding the supply chain, driven to improve performance and that in a good team environment”

Approach

Project-based and structural support

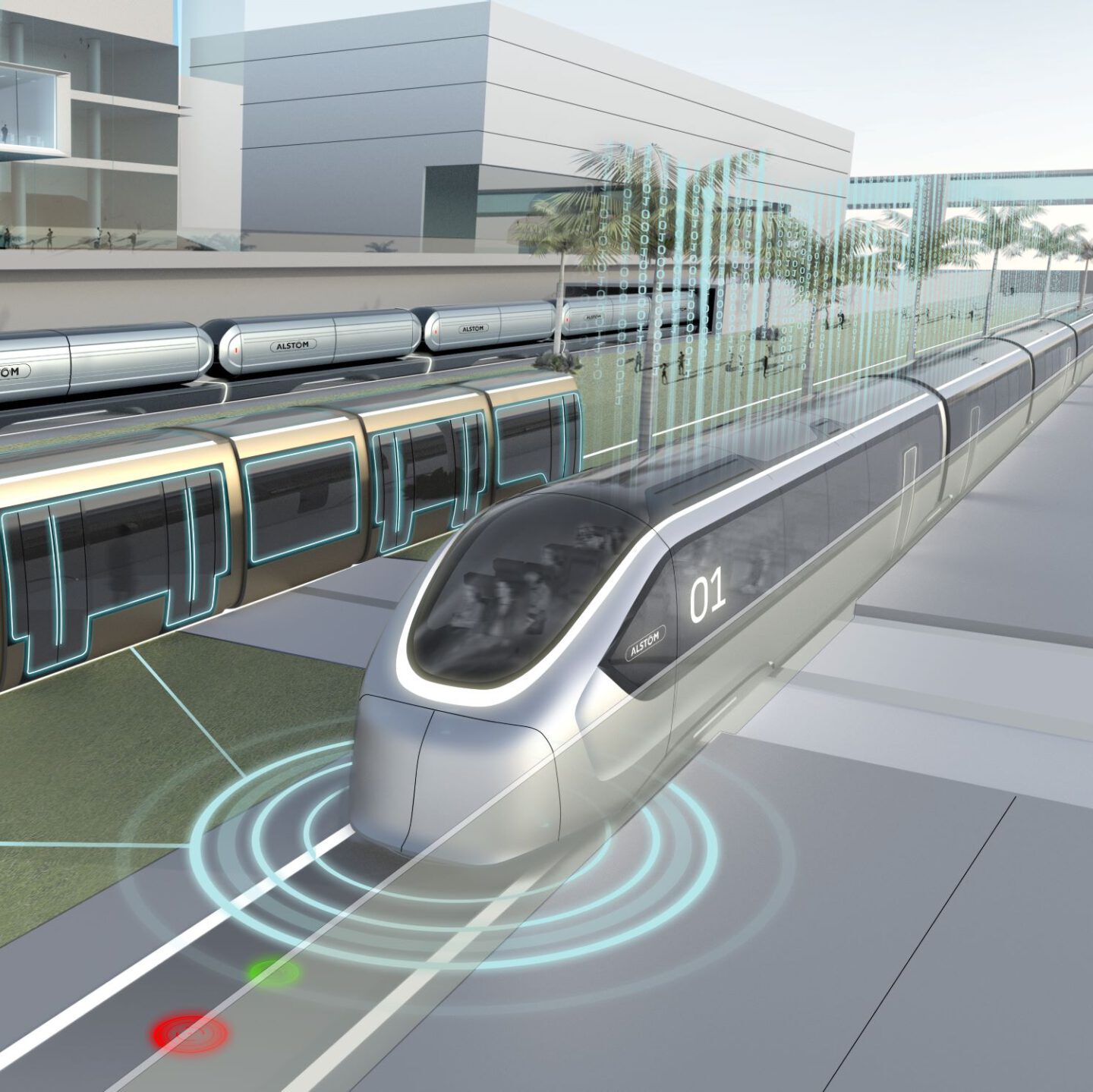

Alstom Transport is a manufacturer of rolling stock and signalling systems. Various regional and national carriers use Alstom products. Alstom’s branch in Ridderkerk supplies and repairs spare parts for customers in the Netherlands. In addition, parts of new traction installations are built at this location for customers worldwide.

In order to be able to meet new availability agreements with customers, Alstom was looking for structural support of its inventory planning with tooling and tactical planning capacity. Through Planning Services, Gordian provides various services to Alstom.

A shift in organizational focus, from new construction to repair, created the need to establish an improved supply chain. To achieve the most important goal, improving the performance towards customers, Gordian provided an interim supply chain manager to help streamline Alstom’s supply chain.

Gordian supports Alstom in the optimal design of the ERP system and the development of tailor-made tooling, if the current systems cannot meet new requirements.

Result

Collaboration pays off